Car designing a brief explanation

Air resistance

In this site we are talking about the concept of cars building and designing and

We started by giving a history of the car evolution from the beginning of the pioneer

Years in the end of the 19th century, till the 60th of the 20th century.

This was the time where it is believed that the car industry began to take its present shape, the mass production shape of many types of cars, from small

economical cheap cars to big luxury expensive cars.

And we took some examples of classic cars that is still found to date and very popular all over the world for its value and classic characteristic.

Its time to move to our main subject, car designing.

In this page we will not go deep in car designing, because this involves some implementation of graphic designing that might be unknown for many people.

I am not a graphic designer or a

car designer myself but I have some knowledge that I will share

With whoever wants to take a brief idea about the way things are done inside the secret Rooms of car designers.

When a car is designed every thing must be taken into consideration because car designing is the not only an art of creating beautiful looking cars, but the way a car handles on the road is directly

connected to its design, letís take a demonstration of a sports car example.

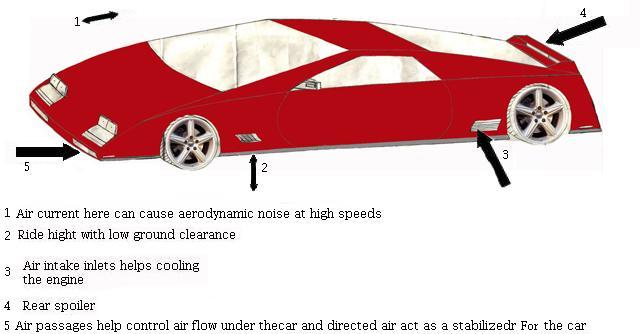

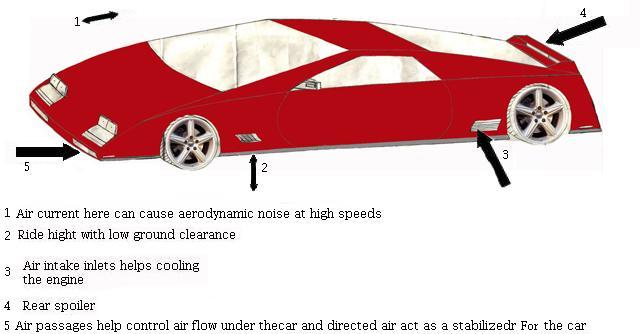

Watch the low profile of the car from the ground (Ride hight) as the car is very near the ground this prevents the air from moving under the car, strong air current

Under the car causes it to be lifted off the ground at high speeds and lose it grip on

The road and there is a possibility that it might roll over itself, air only enters from special allocated entrances in the car front spoiler (Air passages), this controlled air passage is intended to make the air act as a stabilizer to the bottom of the car, the cold air also

Helps in cooling the brakes to ensure it doesnít get hot so the braking force remains the same after continuous braking for a while.

Watch the low profile of the car from the ground (Ride hight) as the car is very near the ground this prevents the air from moving under the car, strong air current

Under the car causes it to be lifted off the ground at high speeds and lose it grip on

The road and there is a possibility that it might roll over itself, air only enters from special allocated entrances in the car front spoiler (Air passages), this controlled air passage is intended to make the air act as a stabilizer to the bottom of the car, the cold air also

Helps in cooling the brakes to ensure it doesnít get hot so the braking force remains the same after continuous braking for a while.

The car also has front and rear air passages although the rear ones are small, some cars feature big air passages that also creates cold air stream that help cooling the engine removing some of the load from the cooling system, because high speeds means that these cars can be really hot, and therefore engine cooling has to be really

Good and effective.

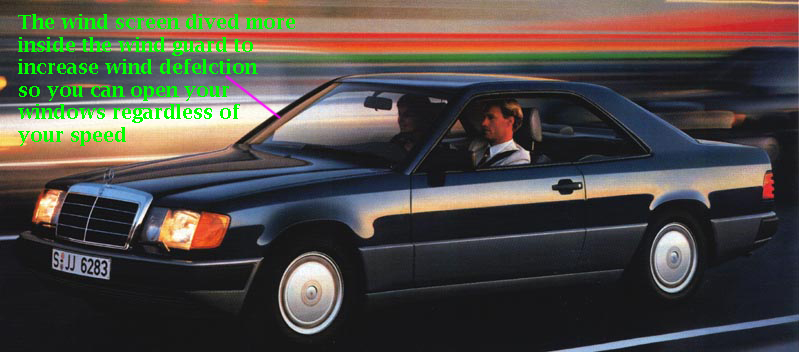

The wind screen area is another place for aerodynamic care, the air that passes over the car engine compartment in the front reaches there, it is then

obstructed by the wind screen that is some what vertical, this causes some resistance this air stream moves also beside the front windows of the

car causing you to hear noises if you open your windows while driving fast (aerodynamic noise) which is found in some poor designs.

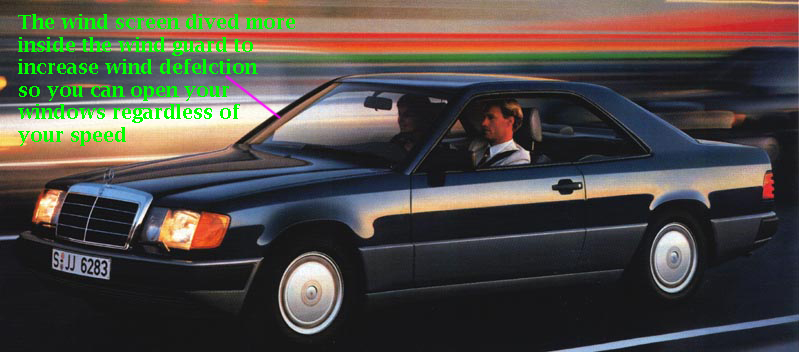

In 1971 &1985 when Mercedes Benz built its new W 116 & W 124 it tried to minimize this problem by the examples below.W116 450SEL 6.9

W124 300CE

these are only demonstrations of how to solve aerodynamic noise problems, and how designers think when dealing with design problems, because

Air stream could be a real problem around the wind screen and not only some irritating noise.

W124 300CE

these are only demonstrations of how to solve aerodynamic noise problems, and how designers think when dealing with design problems, because

Air stream could be a real problem around the wind screen and not only some irritating noise.

The rear end of the car is another important area that must not be ignored.

The rear end carry the other half of the car weight and the stability of the car and its handling on the road depends so much on the weight distribution

between front and rear of the car, how ever a 50 to 50 % is not always liked by designers.

This is a part of the car building cycle that designers cooperate with mechanical engineers in, because the engine adds weight and the suspension of the

car also counts, generally the more weight the rear end of the car has the more stable it becomes but this is not the rule here because heavy rear ends

might slow the car acceleration a little bit and may also cause stability loose.

One of the best solutions to deal with stability problems on the back end of the car was by adding air spoilers, as there name states they spoil the air

action as a factor of stability loose in high speeds by causing air streams to pass around it making the car heavier and more stable at speeds.

The bumpers of the cars today in most cars is protruded down wards to form a front spoiler front spoilers can control air passage under the car, the rear bumpers also have spoilers

under it, some cars especially sports cars like to make exhaust outlets, so that the car exhausts shows out of them with a shiny chrome painting

for a more stylish and sporty look.

Side skirts also acts to redirect the air passage in the car sides and add more style to it.

the suspension system

Now letís talk about another important part that aids a good design in stabilizing the car at high speeds, the suspension system.

"Suspension," when discussing cars, refers to the use of front and rear springs to suspend a vehicle's "sprung" weight.

The springs used on today's

cars

and trucks are constructed in a variety of types, shapes, sizes, rates, and capacities. Types include leaf springs, coil springs, air springs, and torsion

bars. These are used in sets of four for each vehicle, or they may be paired off in various combinations and are attached by several different mounting

techniques. The suspension system also includes shocks and/or struts, and sway bars.

Back in the earliest days of automobile development, when most of the car's weight (including the engine) was on the rear axle, steering was a simple

matter of turning a tiller that pivoted the entire front axle. When the engine was moved to the front of the car, complex steering systems had to evolve.

The modern automobile has come a long way since the days when "being self-propelled" was enough to satisfy the car owner. Improvements in suspension and

steering, increased strength and durability of components, and advances in tire design and construction have made large contributions to riding comfort and

to safe driving.

The suspension system has two basic functions, to keep the car's wheels in firm contact with the road and to provide a comfortable ride

for the passengers.

A lot of the system's work is done by the springs. Under normal conditions, the springs support the body of the car evenly by compressing and rebounding with every up-and-down movement. This up-and-down movement, however, causes bouncing and swaying after each bump and is very uncomfortable to the passenger. These undesirable effects are reduced by the shock absorbers.

So suspension is not only for comfort it is also a big participant in the car road stability at high speeds.

Cadillac allegedly produced the first American car to use a steering wheel instead of a tiller.

Two of the most common steering mechanisms are the "rack and pinion" and the standard (or recirculating-ball) systems that can be either manual or

assisted by power.

The rack and pinion was designed for sports cars and requires too much driver muscle at low speeds to be very useful in larger, heavier cars.

However, power steering makes a heavy car respond easily to the steering wheel, whether at highway speeds or inching into a narrow parking place, and it is normal equipment for large automobiles.

Now days most German cars use an electro hydraulic steering system, Visteon Automotive Systems has developed an Electro-Hydraulic Power Assist Steering (EHPAS) system. This low-cost system uses conventional hydraulic power steering components with an electrically driven and electronically controlled power steering pump electronic control system take information from the engine control unit (ECU) and determines how much assistance you need. This paper presents the Visteon EHPAS system and its development process. This process began with analytical modeling of the EHPAS system and integration of these models with a two- degree-of-freedom (2DOF) vehicle model. These models were critical for system analysis and control strategy design. The EHPAS system sizing procedure and control strategy performance optimization were verified with the use of a real-time computer designed by Ford Motor Company, and by specially designed Visteon test benches. Finally, EHPAS-equipped test vehicles were tuned for high performance, providing better feel and fuel economy than conventionally equipped baseline vehicles because conventional

power steering gets its power from a belt attached to the engine crankshaft which means that the more assistance you get the more load added to the crankshaft unlike electro hydraulic steering system that doesnít do this.

So now after this short briefing we all have an idea whatís going on.

Hope you learned some thing.

Watch the low profile of the car from the ground (Ride hight) as the car is very near the ground this prevents the air from moving under the car, strong air current

Under the car causes it to be lifted off the ground at high speeds and lose it grip on

The road and there is a possibility that it might roll over itself, air only enters from special allocated entrances in the car front spoiler (Air passages), this controlled air passage is intended to make the air act as a stabilizer to the bottom of the car, the cold air also

Helps in cooling the brakes to ensure it doesnít get hot so the braking force remains the same after continuous braking for a while.

Watch the low profile of the car from the ground (Ride hight) as the car is very near the ground this prevents the air from moving under the car, strong air current

Under the car causes it to be lifted off the ground at high speeds and lose it grip on

The road and there is a possibility that it might roll over itself, air only enters from special allocated entrances in the car front spoiler (Air passages), this controlled air passage is intended to make the air act as a stabilizer to the bottom of the car, the cold air also

Helps in cooling the brakes to ensure it doesnít get hot so the braking force remains the same after continuous braking for a while.

W124 300CE

these are only demonstrations of how to solve aerodynamic noise problems, and how designers think when dealing with design problems, because

Air stream could be a real problem around the wind screen and not only some irritating noise.

W124 300CE

these are only demonstrations of how to solve aerodynamic noise problems, and how designers think when dealing with design problems, because

Air stream could be a real problem around the wind screen and not only some irritating noise.